Radiolab about automatic thread quality inspection system

We discussed the development of innovations in Russia and in the world as part of the program “Radiolab” on the radio station “Silver Rain”. CEO Dmitry Lavrinov spoke about the development of the Geomera project and the needs of the pipe industry in thread quality control. We talked about how we measure threads using laser scanning and our unique software. Judging by the WhatsUp chat, our tech an business tales gathered positive feedback from the audience. We conclude that we were able to get the topic across to the people. Thanks to presenters Lyudmila Zyzo and Alexey Nazarov for timely and rational paraphrasing of the information for greater understanding. Indeed, for Russia the topic of oil and gas production, as well as related problems and challenges, is very clear and close. Listeners know how the accident-free work is important for ordinary employees during well drilling and upstream. All the more so because many Russians have relatives, friends and acquaintances working in the oil industry. That’s why many people have heard about drilling accidents firsthand.

Simply about the thread measuring system

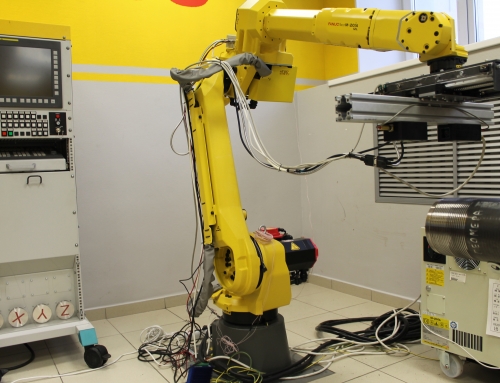

Explaining what we do is simple enough. It is no secret that our country, like many others, depends on oil and gas production. In order to produce them, drilling companies have to drill wells on land and on the sea shelf. Sometimes wells are over 4 kilometres long. One after another, the pipes are lowered into the well, increasing the drill string. The pipes are connected by the threads. Due to high loads and aggressive environment, breaks often occur at the thread connections. This happens at great depths and results in accidents, high financial losses and environmental pollution. Threads are still inspected manually in pipe mills around the world. This leads to defective products. Consequently, either the manufacturer suffers a loss if the defect occurs, or the buyer suffers a loss if the accident occurs. We develop fully automatic laser thread measurement systems. If our systems are put into the pipe production, it will be possible to predict the wear and tear of the equipment and completely eliminate defective products. Therefore, the manufacturer will increase productivity and the buyer of the pipe will avoid accidents.

Leave A Comment